zouk progress.....

As promised, I'm making a pair of these, the plan being that my beloved client will have the choice of two, and I'll keep the other.....

so, having had a bunch of free time yesterday and today after work, there has been progress.......

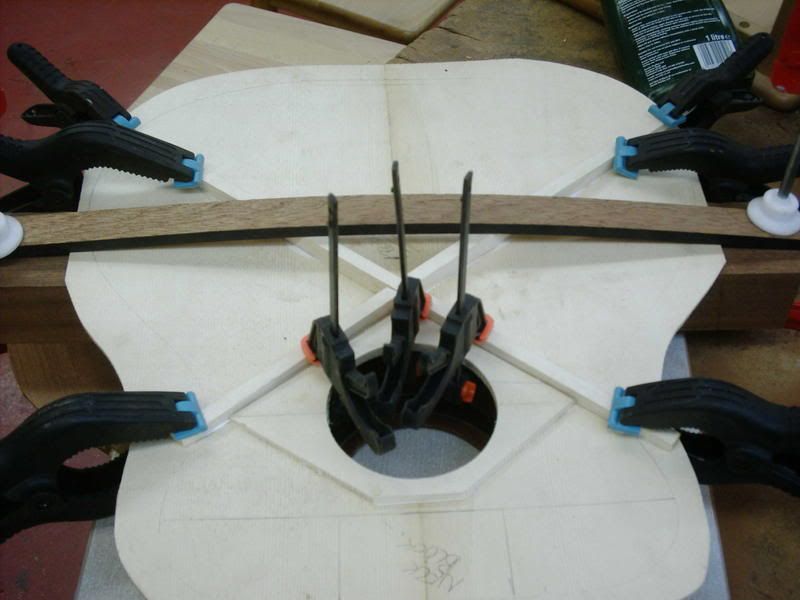

the back is on the first one.....

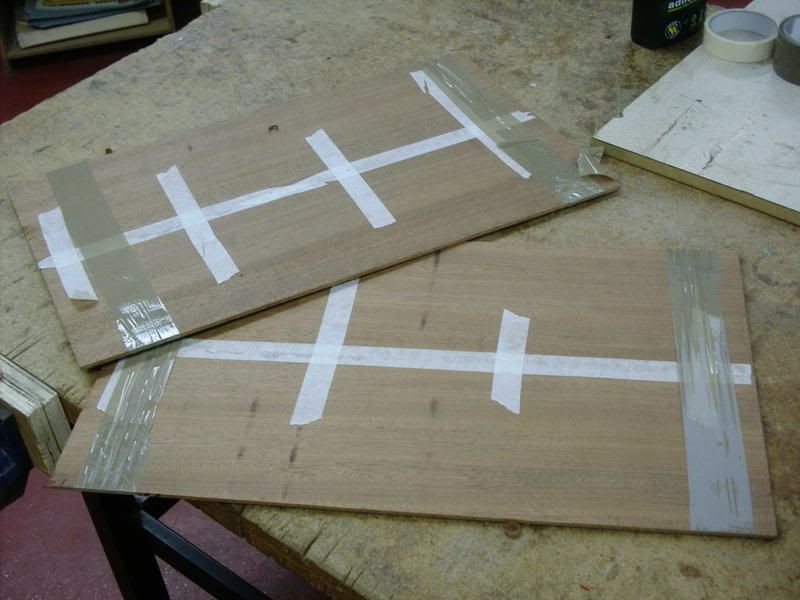

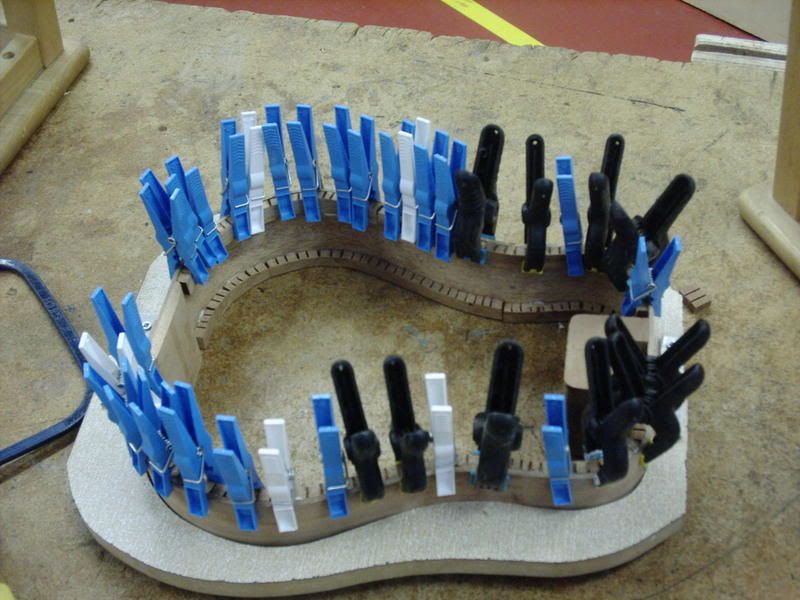

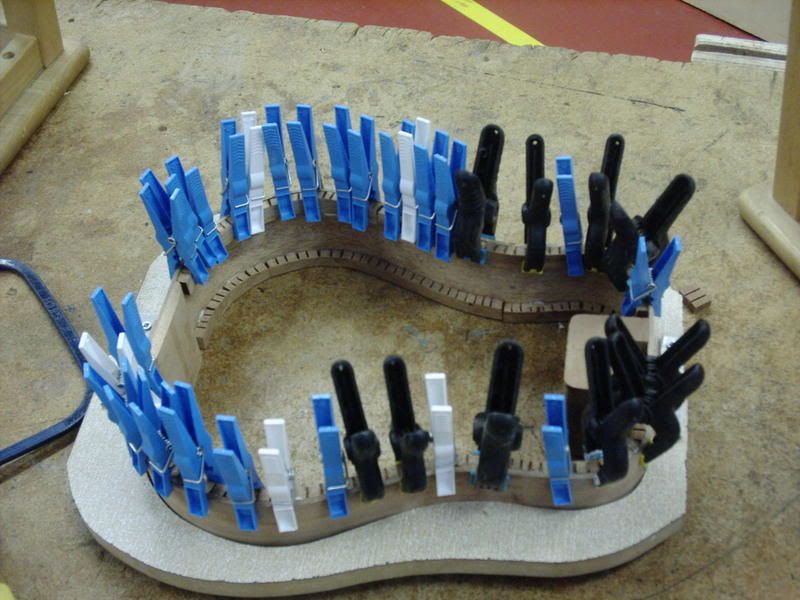

and as the first has vacated the mould, the sides of the second are bent .....

neck and tail blocks fitted and linings started.....

now unfortunately, our circular saw is out of action in school. we had a new one instaslled, but a baboon was incharge so to operate it, the following process is needed.....

1 start the saw

2 leave the saw unattended (running) and walk 75 yards outside to the extractor fan store, unlock the door, start the extractor,

3 lock the store again walk the 75 yards back and find that three pupils have evicerated themselves on the unattended saw in the meantime.....

and if they haven't, if the saw is stopped, for instance to adjust the width of the cut etc, then the extractor stops too. To use technical terms, it's all a bit pants, so HOPEFULLY this will be sorted this coming week and I'll be able to cut the lovely Spruce brace wood for the tops.

in the meantime, I've started on another dread mando!!

I just can't help myself!!