After marking out the rough neck profile, cut it with the band saw.

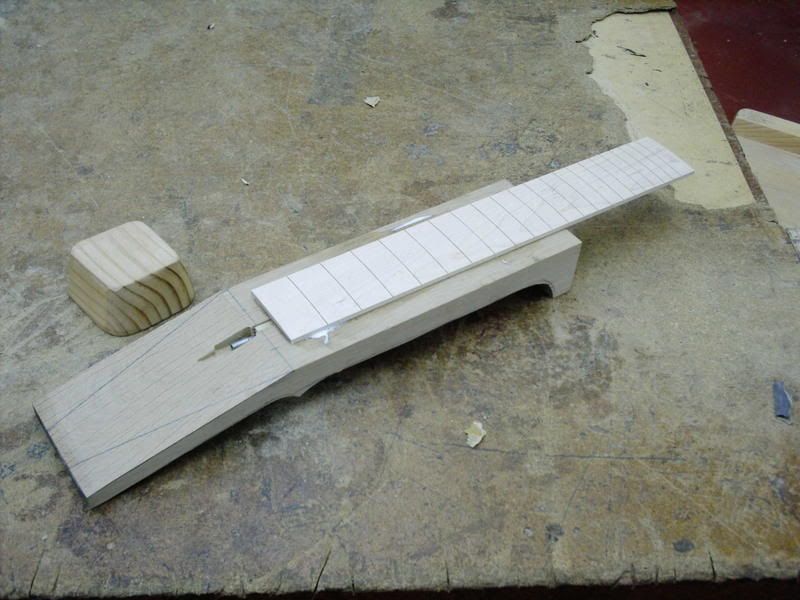

Then assemble the bits so far. trussrod in the slot, fingerboard on top, LINED UP WITH THE ORIGINAL NUT MEASUREMENT!!!! this is important!!

Then assemble the bits so far. trussrod in the slot, fingerboard on top, LINED UP WITH THE ORIGINAL NUT MEASUREMENT!!!! this is important!!and clamp with as many clamps as you can fit onto the thing. All this was done during my lunch break, so this ISN'T the time consuming bit.

let the glue dry. (THIS is the time consuming bit!!)

you'll be left with some wedges, and other various offcuts. Your mum will appreciate a nice door wedge, or oak is great if you cut it into 1/2" blocks and smoke fish over them...........

Once cut up an ex-Bushmills whiskey barrel for smoking fish over. %0 years with Sherry maturing in it then another 50 with the best whiskey in the world all over fine Limousan oak. can you even start to IMAGINE how good that smoked fish was?

Once cut up an ex-Bushmills whiskey barrel for smoking fish over. %0 years with Sherry maturing in it then another 50 with the best whiskey in the world all over fine Limousan oak. can you even start to IMAGINE how good that smoked fish was?OK, clamps off and we have something which starts to look like it might some day be a neck.......

Some more abuse with the band saw and...........

TaDah!!!!

OK, my camera ran out of batteries at this point so I don't have a pic of the ectra block of wood clamped onto the bottom of the heel to give the extra depth needed.

other build news.........

the doubleneck is into the finishing stage. a coat of Danish oil on the back & sides shows up glue splodges that still need sanded out. the Bridges are roughed out but not slotted or drilled yet.

the cutaway mando has the neck on, but no frets yet.

No comments:

Post a Comment