tuners on....

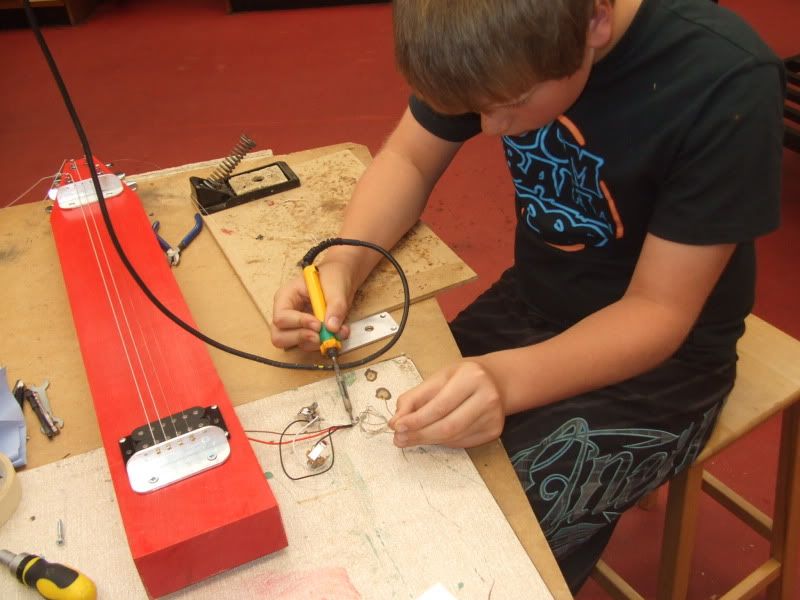

pup in and the volume pot and jack socket soldered together......

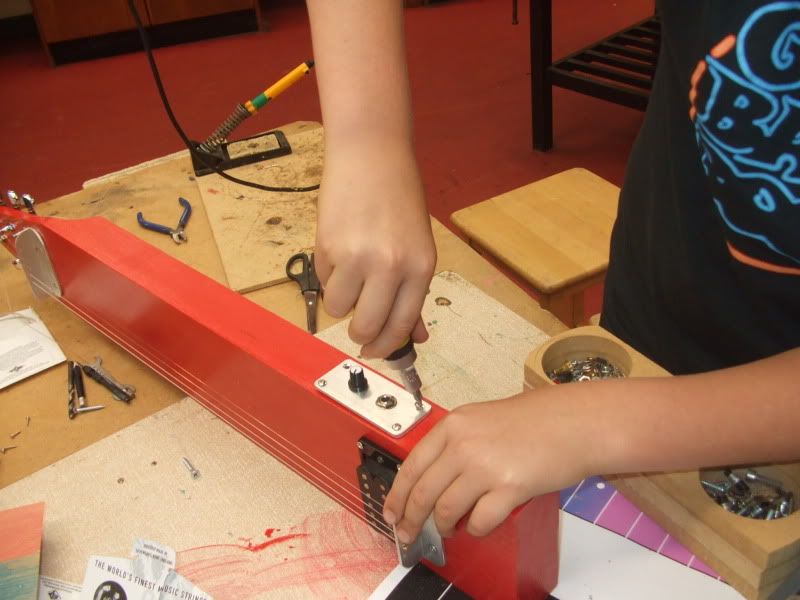

control plate screwed into place.....

and once the fret layout is printed and stuck on under a sheet of clear acrylic......

its playable!!

in the car and heading home before 3 pm!!

he did the vast majority of the work.

I marked stuff out for him and did the curved cut under the head, and did the fretboard layout and made the acrylic cover for it, but he did ALL the rest.

as I'm typing this all I can hear is him playing "another one bites the dust" and "smoke on the water"!!!