a ruler, couple of pencils, a hacksaw blade and some sandpaper.

the following pics are taken from several different instruments, but they show the process!

click on a pic to enlarge.

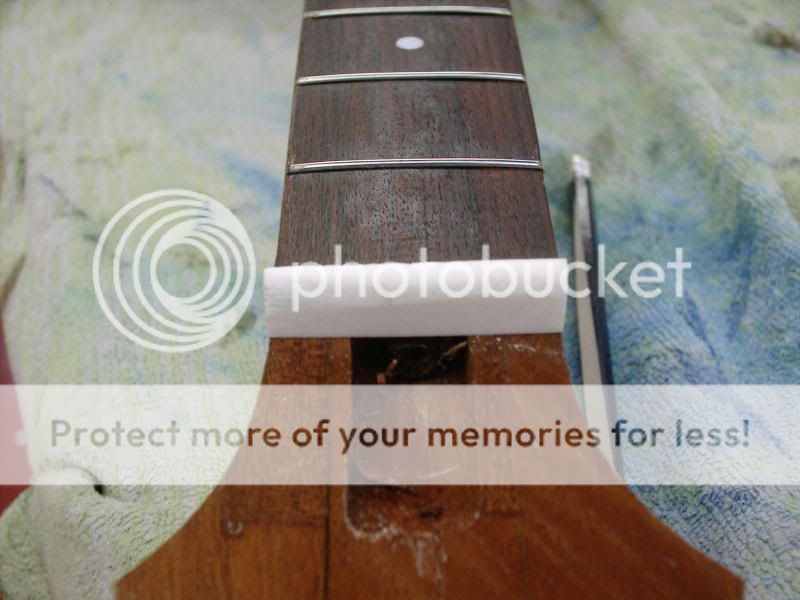

cut & file it to the right length

then make a pencil like this......(I lean it onto the sander)

so that you can mark where the top of a zero fret WOULD be

then shape the top of the nut down to about 1.5mm above that line.

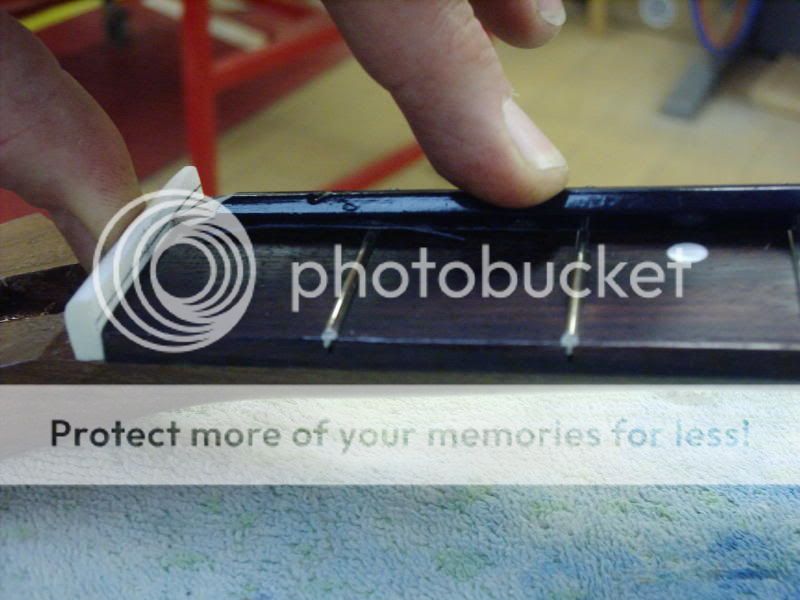

now mark where your slots will be.....

and cut them. DON'T go down to the line.

I use a bandsaw for the initial cuts, but a hacksaw does the job just fine.

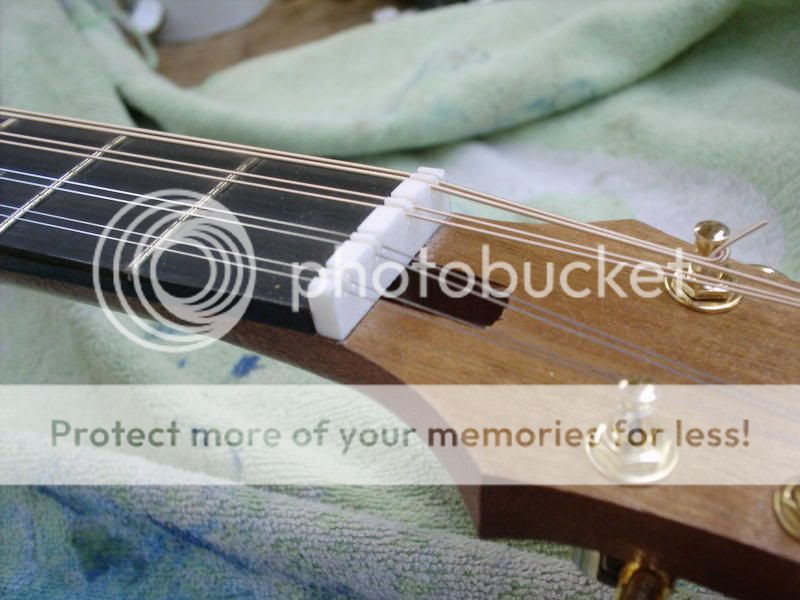

glue it in (a couple of drops of CA (superglue))

then string her up...

(the eagle eyed among you will spot that this is now a bouzouki & not the guitar that I started, but live with it, OK!!!!

the strings will be too high.

lift the strings out 1 at a time and use a saw blade, (or you COULD use a really expensive set of nut files) to bring the slot down to the desired height. DON'T GO TOO LOW!!!! Note the bit of tape to stop the saw marking the headstock. DON'T ask why I found I needed to do this!! The slots need to slope down away from the fretboard a little so that the highest point of the slot is where the string leaves the nut on it's long trip to the bridge.

finish the bottom of the slot with a cast off piece of wound string, just to buff it smooth.

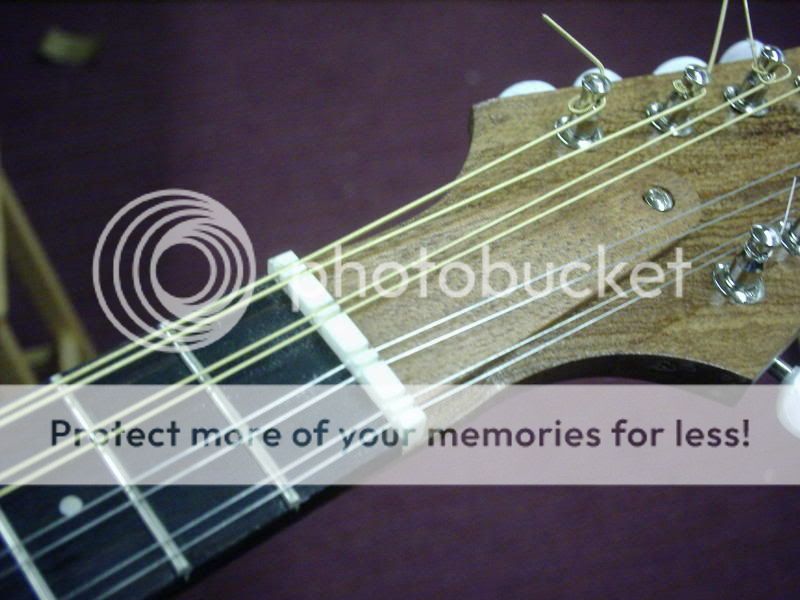

job done!!

OK, OK, this is a third instrument, a mandolin!!

you WILL stab yourself at least 17 times on the sharp string ends doing this.

Oh yes.......